Knives are a tool which we use every day in our lives, but how often do we stop to consider the history behind them and how they came to be in the shapes and forms which we enjoy today? If you are like me you have probably taken them for granted, but also if you are like me, you could not manage to get through the day without them! Here is the evolution of knife design from Paleolithic to Present Day.

The Evolution Of Knife Design Explained

Stone Age: The Oldowan Knife

Back in the Stone Age prehistoric man created knives and tools out of stone. That is why it is called the “Stone Age!” This is the oldest known stone tool industry known to modern man. The Oldowan Knife is the earliest evidence we have of cultural behaviour.

Shaped from pieces of stone, ancient man used other stones (stone hammers) to chip away flakes from flattish shaped rocks to create sharpened edges that they could then use for cutting, chopping and scraping. There is also evidence that they may have used them as tools for cutting plants and butchering animals.

Copper Age: Flint Knives

As man became more adept and began to discover and mine minerals such as gold, silver and copper, they also realised that these minerals could be melted and cast into a variety of shapes and sizes. Crude molds were made and then the melted ore was poured into the molds and allowed to harden. Once hardened they would then be able to hone the edges by hammering them into sharpness.

This also meant that old or broken knives could be re-melted and re-cast to create new ones! They may not have been as sharp as the old stone knives, but they were much stronger!

Bronze Age Knives

Knives were adapted from copper to bronze in the middle Bronze Age. Bronze was much sturdier than copper. By the late Bronze Age, the creation of knives had evolved to the point where there were more than one kind of knife having been created and used.

Eight distinctive types have been discovered in Britain. Tangled leather working, triangular perforated, hot backed, double-edged socketed, single-edged tanged, single-edged socketed and single-edged solid hilted. A mix of copper and tin made these knives much lighter in weight than stone, also making them easier to carry and transport, as well as being much easier to shape.

Roman Age/Iron Age Knives

With the Roman Age came even more advancements. At that time high carbon steel was being regularly manufactured in India, but it was quite costly and difficult to produce. At one point, due to the unavailability of tin, people began to use iron in its place. Hence, it was called the Iron Age.

Once tin became available again, iron was still regarded as being much cheaper, stronger and lighter and the use of bronze declined. Iron required higher temperatures and specialized furnaces in order to enable it to reach a melting point. Mixing carbon with the iron created steel. The higher the carbon content, the harder the steel. It was at this time also that knives became more common amongst people from every class, from the highest of nobles down to the poorest of serfs.

Knives at this time were also mainly used as weaponry. The main exception would have been the wealthiest people who also used them as eating utensils in addition to their plates. Wealthy men would use their knives to cut their own meals as well as the meals of their female companions.

Thracian Sica Knives

During the Thracian Sica period, curved dagger-like knives were introduced. This was a major change in knife design. These curved knives were often quite ornate, being heavily decorated. The higher a man’s status the more heavily decorated the knife would have been, a practice which continued into the Ottoman age.

Ottoman Era Knives

During the Ottoman era the blades of knives straightened out more rather than being curved, but they were still quite heavily decorated with floral decorations and gilt.

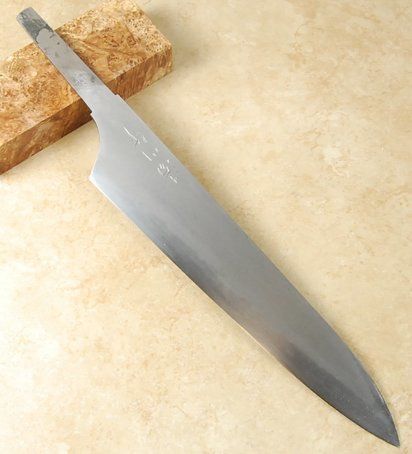

Deba Bocho Knives

The 17th century introduced Deba Bocho Knives, Japanese style kitchen knives. These were primarily used to cut fish but were also used to cut meat and were found in sizes up to 12 inches in length. These knives were the preferred tool for traders working at Tokyo’s famous Tsukij fish market.

For centuries the Master Swordsmith Chiyozuru Kuniyasu had traveled from Tokyo to the Fukui prefecture looking for water which was considered to be the most suitable for forging his Samurai swords. At this time, the end of the Tokugawa Shogunate meant that Japanese swords were no longer permitted to be worn in public by Samurai. These smaller Japanese forged knives came in a variety of shapes and sizes.

Paring Knives

Paring knives were introduced in France during the late 1600’s early 1700’s. This came about due to the will of a French Cardinal named Richelieu. Cardinals at that time were considered to be important members of the French court. Cardinal Richelieu detested the tradition of men at the Court in using sharp knives to scoop up their food from the table as well as to pick their teeth. He was able to use his influence with King Louis XIV to ban the use of sharp double-bladed knives not only from the court but also throughout the whole country, with the purpose in mind of reducing violence.

Solingen Knives / Henckles

The 19th century saw the rise of quality knives created by the Germans who were at the forefront of technology at that time. Solingen, Germany, was known for its excellence in industrial tool production. What began as the production of sabers and swords evolved into the production of shaving blades, scissors, and pocketknives. Even today the Germans, along with the Japanese, are the vanguards quality knife production. In 1839 the German company Zwilling A J Henckles invented Friodur, a special ice-hardened no-stain steel, which continues to be used in modern times.

Santoku Knives

Japanese Santoku knives were the next step in the evolution of knife design and most chef’s today are proud owners of their own sets of Santoku knives. General purpose kitchen knives are the perfect combination of design and heft with their uniquely shaped handles and sheep’s-foot blades. The two work in perfect harmony by matching the blade’s weight and width perfectly to the blade tang and handle. Providing a more linear cutting edge, the Santoku has limited rocking travel. If used properly as designed, they seem to hold their edge longer. Typically, they have no bolster, but many incorporate scalloped sides.

Granton Knives

Granton is the trademark of the Granton Knife Company in Sheffield, England, an area which is well known for its history of steel-works. It is quite common for many knife companies to use the term Granton to describe a particular knife blade edge which incorporates identical rows of scallops on both sides of the blade. In fact most Santoku knives today also make use of the Granton blade, which really helps to prevent food from sticking to the knife. A Granton edged knife requires less steeling than most other knives. They were originally designed specifically with the professional user in mind.

Honyaki Knives

The Honyaki knife is considered to be the apex of kitchen knives. Forged using just one single high-carbon steel these knives are differentially hardened just like the smauri swords.

Because of their difficulty to forge, and the amount of skill and experience required to produce these special knives there are very few masters in Japan that able to forge Honyaki knives today. They are quite rare and very expensive. They truly embody the art of kitchen tools due to the ultimate skill and precision of true master in the forging of knives.

Ceramic Knives

Finally, in modern days, we have Ceramic knives. Lightweight and dangerously smart, these knives are composed of powdered zirconium dioxide, dry pressed and fired into shape. The blades are sharpened by grinding the edges against a diamond-dust coated grinding wheel, which results in a well-hardened blade which holds its sharpness longer than conventional steel knives.

Although the edge of a ceramic knife is also harder than steel, it is also more brittle and less tough. They can and will break if not cared for properly and carefully. Specialized services are required for sharpening their edge due to their unique and specific qualities. It is not recommended that you use them to chop through bones or frozen foods, although they certainly excel at boneless meats, fruits, vegetables and bread.

Conclusion

I hope that you have enjoyed reading about the evolution of knife design throughout the centuries and that you have been able to gain a deeper appreciation for the thought and care which has been put into these very important and valuable tools in our modern-day kitchens!

Thank you Marie for this article. I love learning new things.